2025-02-14

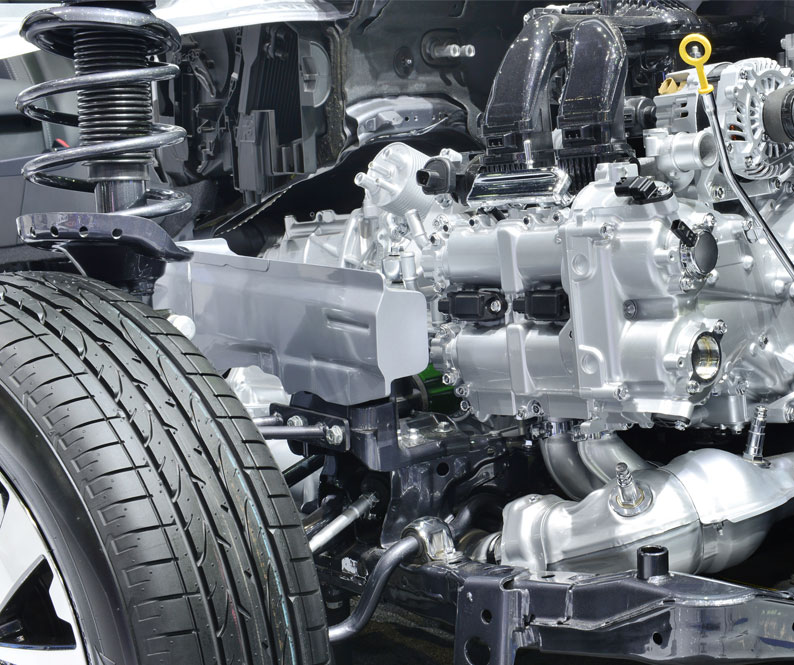

Copper Casting: A Cornerstone of Automotive Manufacturing

Copper casting, a time-honored metalworking technique, is playing an indispensable role in the automotive industry, thanks to its unique physical and chemical properties, reliably supporting the industry's development.

More

2024-07-19

Application of Automation and Smart Manufacturing Technologies in Copper Forging Industry

In the evolution of manufacturing, automation and smart manufacturing technologies have become crucial focal points. These innovations are revolutionizing traditional copper forging industries, enhancing efficiency, and ensuring key quality improvements.

More

2024-04-12

Metal Refinement Manufacturing: Exploring Nine Casting Methods and Their Applications

Casting is a manufacturing process where metal is melted and poured into molds to solidify and take shape. Casting methods can be categorized based on the mold material, production technique, and pouring method. Below are nine common casting methods, their advantages, challenges, and applications:

More

2024-03-07

Optimizing Copper Casting Processes: Preventing Common Defects and Enhancing Casting Quality

Copper casting is an ancient process known for its excellent electrical conductivity, thermal conductivity, ductility, and malleability. It is widely used in electronics, electrical appliances, machinery, and construction. However, the copper casting process can also result in various defects that affect the quality of the castings.

More

2023-11-06

Copper Forging: Advantages and Challenges in Multi-Industry Applications

Copper forging technology has long been a crucial manufacturing process across various industries, known for its versatility and exceptional performance. However, this widespread application also brings specific challenges in different sectors. This article delves into the applications of copper forging across various industries, analyzing its advantages and potential challenges, while also providing corresponding solutions.

More

2023-10-04

Precision Technology Revolution: Exploring the Operation Principles & Basic Function

CNC machines play a pivotal role in modern industry, revolutionizing manufacturing processes with their precision and efficiency. Centered around computer technology, CNC (Computer Numerical Control) machines utilize precise programming to control metal cutting, operating through a series of basic function commands such as movement, cutting, positioning, speed control, and tool selection.

More

2023-09-18

The Electric Vehicle Era: Copper's New Opportunities and Key Role

The rapid rise of Electric Vehicles (EVs) not only signifies a revolutionary transformation in transportation but also triggers a significant shift in materials science. In this context, the importance of copper is becoming increasingly prominent, especially within the EV industry's supply chain. As a leader in copper processing, JITO is well aware of the core value of copper in EV technology.

More

2024-07-19

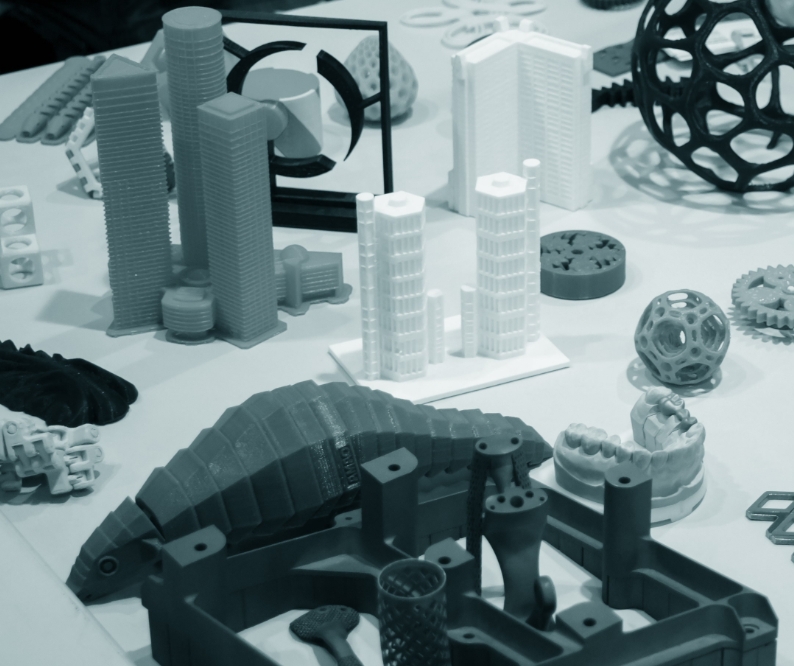

From Prototype to Mass Production: The Optimal Integration Strategy of 3D Printing and Casting Tech

By combining the strengths of both, such as using 3D printing to produce molds required for traditional casting, we can achieve production results that are swift, precise, and economical. Additionally, 3D printing can concentrate on high-tech areas like aerospace or medical equipment, while casting is more suited for mass-produced generic products.

More

2023-08-10

Adapting to EU CBAM Policy and Green Transformation

The recent introduction of the Carbon Border Adjustment Mechanism (CBAM) by the European Union aims to ensure that imported goods have carbon emissions comparable to those produced within the EU. This policy will have a significant impact on the operations and marketing of many local businesses in Taiwan.

More

2023-05-01

Green Casting: The Path to Sustainable Development

In recent years, there has been an increasing global focus on environmental protection and sustainable development, with green casting becoming a more and more important casting method. Green casting emphasizes how to reduce environmental burdens and waste of resources in the production process. It not only helps protect the environment, but also helps enterprises reduce production costs and improve market competitiveness.

More

2023-03-10

The wide application and innovation of forging technology

Copper casting is an important metalworking technique that involves pouring molten copper into molds, allowing it to cool and solidify to form the desired shape and size. This technique has been widely used in various industrial fields.

More

2023-02-23

The difference between CNC lathe and milling machine

A lathe and a milling machine are two common machining equipment used in metal processing.

A lathe is primarily used to machine rotary parts and can produce various shapes of parts such as shafts, sleeves, and gears.

More

2022-11-14

Copper casting applications: Industrial metal parts

Copper casting is an important metalworking technique that involves pouring molten copper into molds, allowing it to cool and solidify to form the desired shape and size. This technique has been widely used in various industrial fields.

More

2022-11-14

Do you know how to distinguish forging and casting?

The finished product of casting has a lower density, while the finished product of forging has a higher density. Therefore, for the same volume: the weight of cast metal is heavier and the strength is weaker; the weight of forged metal is lighter and the strength is much stronger because it has been compressed. Forged products have enough hardness and are not easily deformed. However, even sturdy forged products can be deformed when subjected to strong impact.

More

Popular Articles