From receiving customers' original design requirements, developing and producing samples together, to formal mass production, JITO has been providing many customers with high-quality, low-cost, and mechanically metal parts processing solutions. With our core technology in mechanical processing accumulated over the years, we offer a diverse range of customized services and provide one-stop comprehensive solutions. To expand our service content and meet customers' diverse needs,JITO continues to enhance our capabilities and technologies and seeks diverse cooperative partners to help industrial customers maintain their market competitiveness.

Through continuous communication with customers and understanding their needs, our goal at Ju-Tong is to become a trusted partner in providing the best solutions to our customers. When we receive inquiries or requests from customers, such as for quotations, changes to material types, adjustments to production processes, additional processes, or special rush orders, our contact team prioritizes handling them and continuously "verifies" and "confirms" with the customers to ensure that we truly understand their needs. To achieve comprehensive communication, cross-departmental collaboration between Ju-Tong and our customers is necessary. During the stage of integrating the best resources, all evaluations are based on satisfying customer needs and helping to maintain their competitiveness, with a focus on proposing solutions that bring the best benefits to the customers. In addition to the sales team, our engineering and quality assurance teams are also dedicated to fulfilling our commitments to customers. From creating samples to successful mass production, we establish long-term cooperative relationships with our customers based on mutual trust.

This discussion and technical review process can confirm the feasibility of the required processing and ensure that the parts meet the customer's needs.

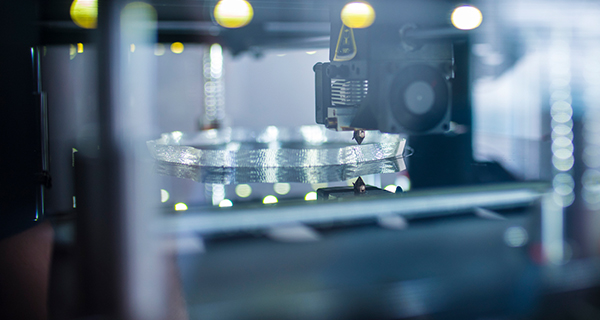

The molds ensure that the produced parts meet the required precision and can fit and assemble together with other parts.