Professional Manufacturing and Processing

Manufacturing and processing of metal products

JITO was established in 1994, mainly providing integrated OEM services and export trade to European, American, and Japanese customers. With the development trend of professional division of labor and globalization competition, we uphold the three major competitive strategies of Professional Technology, Quality Assurance, and Rapid Service. Over the past 18 years, we have continuously expanded our business units, including the copper press casting business unit, aluminum/copper forging business unit, and CNC precision parts processing business unit. We have expanded to three factories from our initial copper casting business, established the copper/aluminum forging business in 2002, and set up CNC precision machining in 2009. At first, we specialized in manufacturing water hardware and mechanical parts related to copper casting. Later, we developed the ability to manufacture more diverse and higher mechanical properties of hardware parts through copper/aluminum forging and CNC machining.

Understand Us

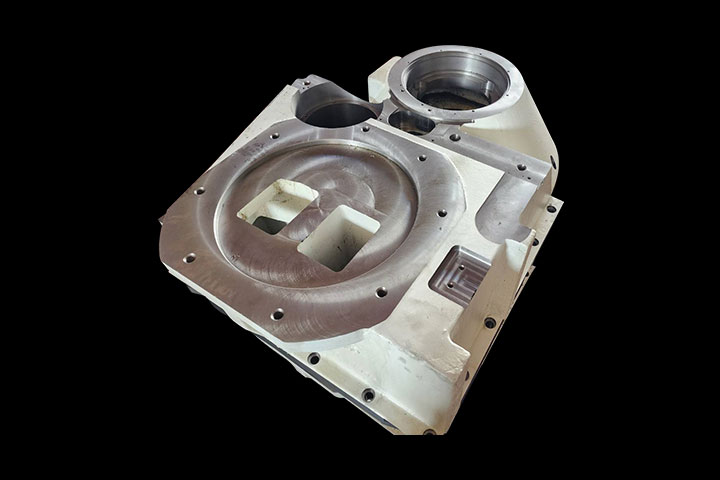

Casting processing

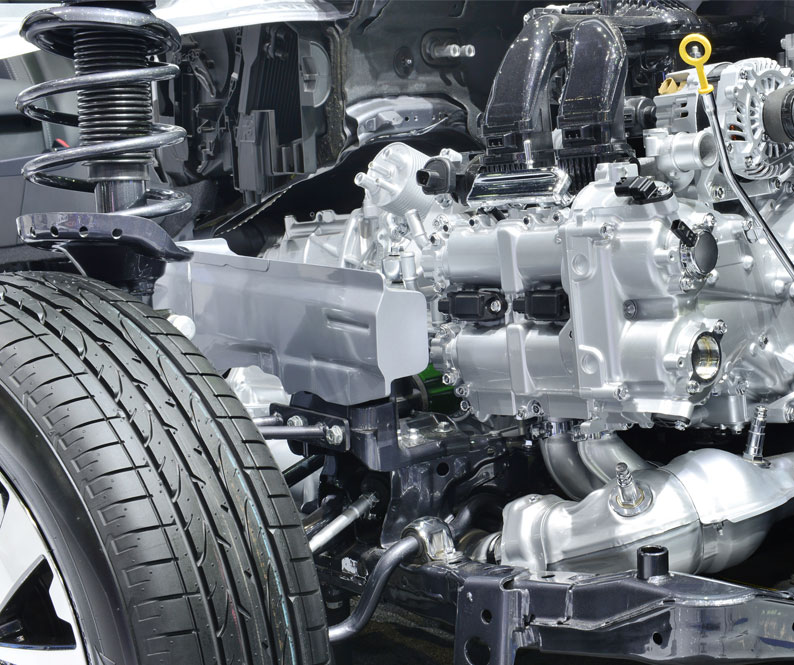

Casting refers to a production technology where liquid material is poured into specialized mold cavities to obtain the desired product shape during solidification, and then post-processing is carried out after taking out the solidified workpiece. Casting technology has a wide range of applications, including industrial manufacturing, automotive manufacturing, household hardware, aerospace industry, etc. Casting is suitable for the production of hollow or complex solid products.

Forging and processing

Forging is a metalworking process that involves applying pressure (ranging from hundreds to thousands of tons) to metal materials by heating them to an ideal processing temperature and using the pressure to shape the metal and fill the mold cavity, in order to obtain certain mechanical properties, shapes, and dimensions. In order to soften the material for easy processing, the raw material is often heated before forging during the process.

CNC Machining

CNC (Computer Numerical Control) machining is a computerized numerical control tool used in the manufacturing industry. It involves the input of NC programs compiled and calculated by a computer, which are then transmitted to CNC machining equipment. The control system integrated within the CNC machine sends instructions to the drives, which in turn drive the motors to perform cutting and machining operations on the designed components.

Applications of Metal Parts Processing

Knowledge of Forging, Casting & CNC Machining

Copper Casting: A Cornerstone of Automotive Manufacturing

Copper casting, a time-honored metalworking technique, is playing an indispensable role in the automotive industry, thanks to its unique physical and chemical properties, reliably supporting the industry's development.

Metal Refinement Manufacturing: Exploring Nine Casting Methods and Their Applications

Casting is a manufacturing process where metal is melted and poured into molds to solidify and take shape. Casting methods can be categorized based on the mold material, production technique, and pouring method. Below are nine common casting methods, their advantages, challenges, and applications:

Adapting to EU CBAM Policy and Green Transformation

The recent introduction of the Carbon Border Adjustment Mechanism (CBAM) by the European Union aims to ensure that imported goods have carbon emissions comparable to those produced within the EU. This policy will have a significant impact on the operations and marketing of many local businesses in Taiwan.

Green Casting: The Path to Sustainable Development

In recent years, there has been an increasing global focus on environmental protection and sustainable development, with green casting becoming a more and more important casting method. Green casting emphasizes how to reduce environmental burdens and waste of resources in the production process. It not only helps protect the environment, but also helps enterprises reduce production costs and improve market competitiveness.

The difference between CNC lathe and milling machine

A lathe and a milling machine are two common machining equipment used in metal processing.

A lathe is primarily used to machine rotary parts and can produce various shapes of parts such as shafts, sleeves, and gears.

Copper casting applications: Industrial metal parts

Copper casting is an important metalworking technique that involves pouring molten copper into molds, allowing it to cool and solidify to form the desired shape and size. This technique has been widely used in various industrial fields.

Do you know how to distinguish forging and casting?

The finished product of casting has a lower density, while the finished product of forging has a higher density. Therefore, for the same volume: the weight of cast metal is heavier and the strength is weaker; the weight of forged metal is lighter and the strength is much stronger because it has been compressed. Forged products have enough hardness and are not easily deformed. However, even sturdy forged products can be deformed when subjected to strong impact.